What Are You Looking For?

What Are You Looking For?

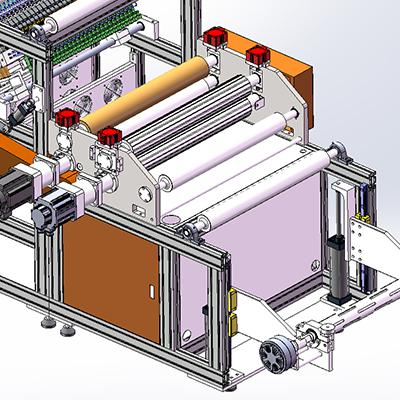

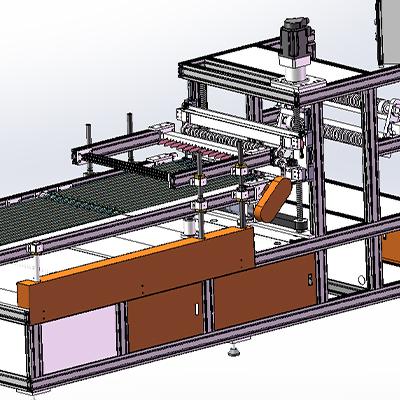

LTWG-1300N/700N 300 Pleat Depth Full-auto HEPA Filter CNC Mini Paper Pleating Machine

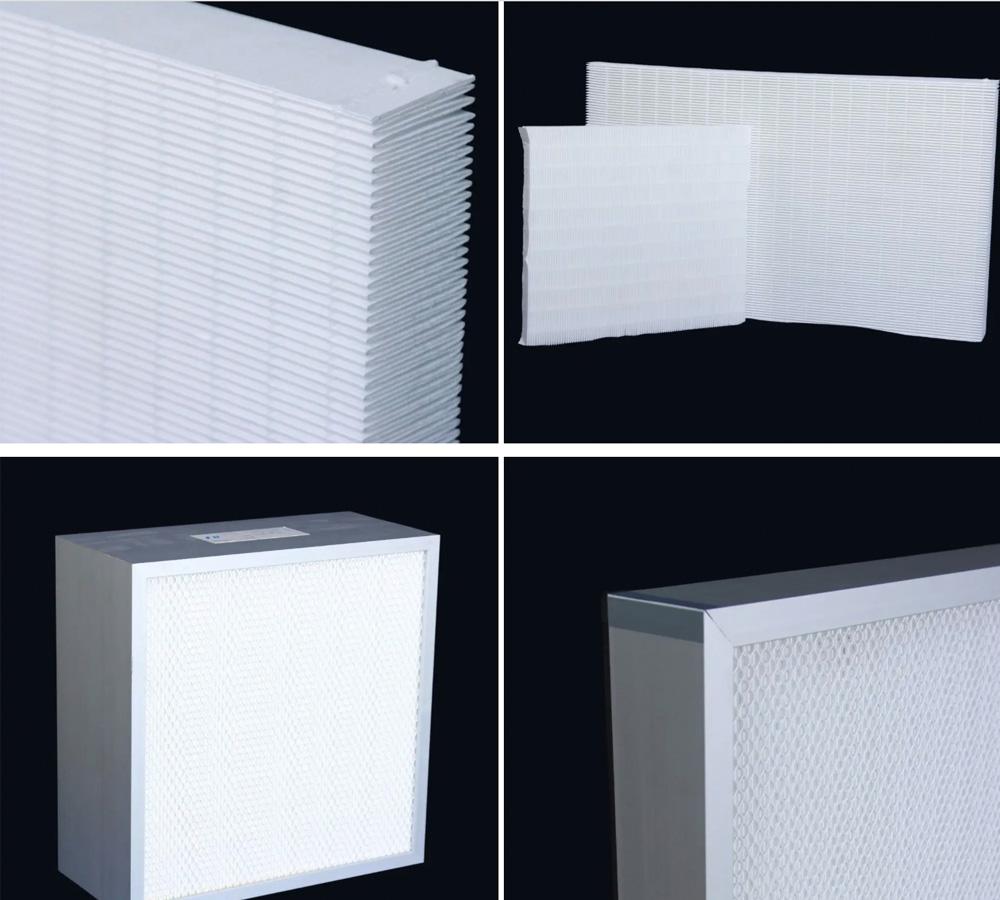

LTWG-300-700II Full auto CNC HEPA filter Pleating Machine Make Up Pleating, Gluing, Conveyor. Operating System Via Touch Screen Interface And It Has Modern Monitoring System. Pleating Height Can Do (20-300mm) Via Pleating Servo Motor.The HEPA Air Filter Of Glass Fiber Material Pleated By This mini pleat production line is Accurate In Size, Flat And Consistent,Thickness Of The Glue Line Is Consistent.

Item No :

LTWG-1300N/700NOrder(MOQ) :

1SETPayment :

T/TProduct Origin :

BENGBU,ANHUIColor :

BLUE,CUSTOMIZATIONShipping Port :

SHANGHAILead Time :

AROUND 30-45 DAYSWeight :

1500KGS

Product Description

LTWG-300-700II is Full auto CNC HEPA filter Pleating Machine is suitable for pleating and gluing of glass fiber materials and paper filter elements of air filters.

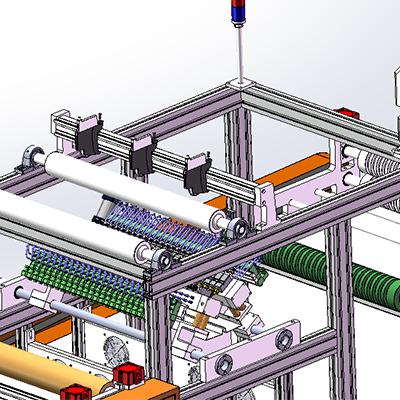

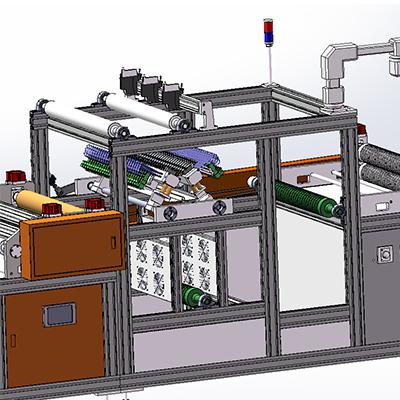

The mini pleating machine production line is composed of eight parts of the material tensioning, servo, pre-slitting, gluing, cooling, pleating and touch screen control and adopts imported scuttling knife, scuttling end face is flat, no rough edge; The rotary pleater filters production line is driven by high precision servo motor to ensure the superior performance of the equipment.By using the speed difference between the two sets of rollers, the folding height can be adjusted (20-300mm) without changing the roller, which improves the working efficiency.Each head has an independent control valve, which can be continuously injected and intermittently injected to adapt to different specifications and different models of products.PLC program control and touch screen operation make the operation easy to understand.The production line is equipped with a cooling system to make the glue solidify immediately after the product is injected, which is convenient for cutting the product.The longer conveyor mechanism is suitable for cutting products of different lengths. At the same time, the rotary filter pleating machine has single side gluing, break number of gluing, staggered gluing, edge gluing and other gluing modes.The parts of the glue spraying mechanism are precisely machined to make the thickness of the glue line consistent.This production line is the first choice equipment for purifier production enterprises to fold high filter element folding glue.

Product specification

|

Mode0l |

Available width |

Production speed |

Available height |

Main power |

Glue applicator |

||

|

Quantity auto gun |

Capacity tank |

Available temperature |

|||||

|

LTWG-100-700 |

650mm |

5-20m/min |

20-100mm |

18kw |

24unit*2lines |

50kg*1unit |

40-230 |

|

LTWG-100-900 |

900mm |

5-20m/min |

20-100mm |

18kw |

36unit*2lines |

50kg*1unit |

40-230 |

|

LTWG-100-1000 |

950mm |

5-20m/min |

20-100mm |

30kw |

38unit*2lines |

50kg*2unit |

40-230 |

|

LTWG-100-1300 |

1250mm |

5-20m/min |

22-100mm |

30kw |

50unit*2lines |

50kg*2unit |

40-230 |

|

LTWG-100-1600 |

1550mm |

5-20m/min |

28-100mm |

33.3kw |

60unit*2lines |

50kg*2unit |

40-230 |

|

Specification |

|||||||

|

Control system |

Touch screen +PLC+Servo CNC |

||||||

|

Available material |

Glass fiber |

||||||

|

Working air pressure |

6kgf/cm2 |

||||||

|

Voltage |

Selectable (380V/220V/410V-50HZ) |

||||||

|

Fold height |

Can adjustment and customized ( Normal is from 20mm to 100mm can adjust by touch screen) |

||||||

|

Use for |

ULPA,HEPA medium pleating and gluing |

||||||

|

Profiler |

|||||||

|

1.PLC+Touch screen control+servo system |

|||||||

|

2.Soft scoring roller system: so can ensure the high quality of the produced filter, No damage to the media/blades (reduce huge scrap),Extending machine life, Reducing noise & vibration. |

|||||||

|

3.Prefect design and reliable components ensure the high quality and excellent performance. |

|||||||

|

4.Both the fiber glass pleating and hot melts dispensing on the same machine. |

|||||||

|

5. Mini pleating machine for HEPA filter,filter for electronic clean room, operating room, the purification workshop GMP pharmaceutical workshop food QS certification. |

|||||||

|

6. It's very easy and friendly for operator. |

|||||||

|

7.Air-cooled pressure control, teflon. coating roller. |

|||||||

|

8.Conveyer belt and the hot melt applicator are all controlled by the PLC. |

|||||||

|

9.Material tension controlled by powder brake and tension controller. |

|||||||

Product Component

Equipment production products